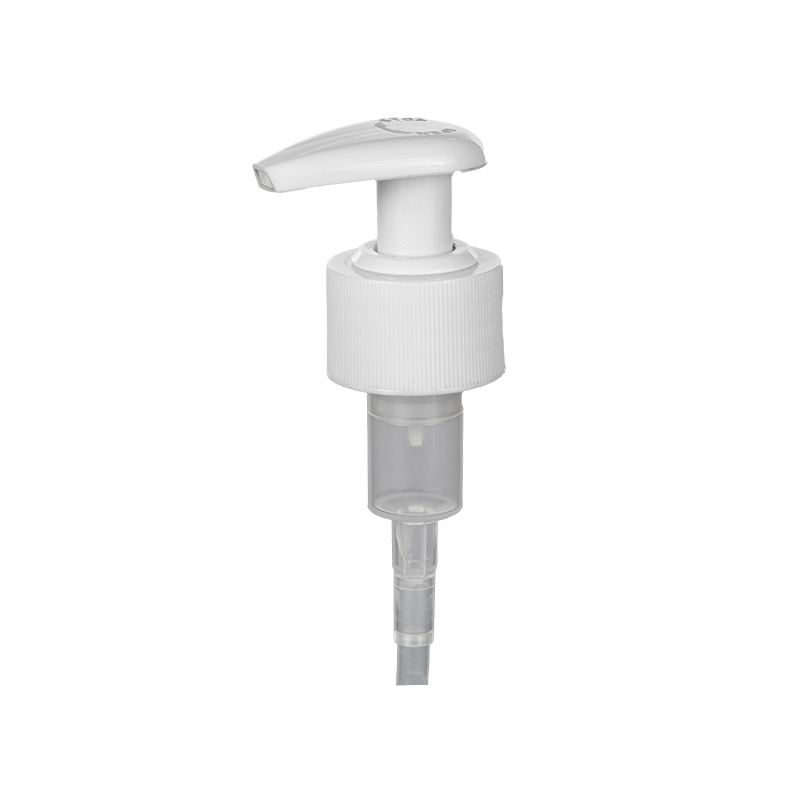

Dispenser pumps are volumetric devices for the continuous application of low- to high-viscosity potting materials. These tools are useful in applications such as sealing beads to component housings and applying adhesives in joining processes. Listed below are a few of the most common types of dispenser pumps. Each type is suitable for specific applications. These pumps are often used for the following: petroleum, lubricant, paint, and potting compound.

These pumps are typically used for measuring epoxy resin. They are available in pairs and are made with oil-coated springs to prevent rusting in the warehouse. They need to be cleaned frequently with isopropyl alcohol to prevent fish eyes and cloudiness. Be sure to label your dispenser pumps so you know exactly how much epoxy resin to use at a time. It is essential to never mix hardener with resin.

When mixing different types of resin, it is important to ensure that they are applied in an even manner. Sharp fillers can clog gears and cause gear wear. In order to avoid these problems, volumetric piston dispensers are ideal for casting and metal foundry applications. These pumps are designed to be rugged and offer high dispensing speeds. They can also be used for filling epoxy resin into molds. However, be sure to read the instructions on the dispensing pump to prevent misapplication of the material.

Dispenser pumps are used in the production of cast parts. In these applications, the epoxy resin is applied directly into the foundry. They are usually sold in pairs and have oil on their springs to prevent rusting in the warehouse. For proper use, it is essential to clean them regularly with isopropyl alcohol to prevent cloudiness and fish eye. These pumps should be marked so that they are not mixed with the hardener and resin.

Epoxy resin is the most common type of resin in foundries. It is used in various applications, including casting, including automotive, aerospace, and other applications in the foundry. In the foundry, it is a very important process and requires precision. It is necessary to ensure that the epoxy resin is applied evenly, and it is also important to make sure that the parts are cast without any errors. There are a variety of dispensing pumps, allowing the operator to precisely measure the amount of resin.

The dispensing pumps are used in the foundry to measure epoxy resin. They are usually sold in pairs, with oil on the springs to prevent rusting in the warehouse. For best results, dispensing pumps are installed in the foundry by the owners. The pumps are essential for the finished product. They are necessary for the manufacturing process of cast iron. There are a few types of dispenser pumps. One is the Epoxy resin dispenser.