A Plastic Screw Cap is a type of closure used to seal bottles. This type of cap is used to package dangerous and hazardous products. Some types are child resistant, protecting children from potentially dangerous products. Other styles have leak-proof seals or are tamper-evident. These are generally used in the health and food industry. But they are also used in cosmetic products. To learn more about Plastic Screw Caps, read on!

There are many benefits of using aluminium caps. A quality aluminium cap can add a premium look to your packaging and give them a high-end look. Another advantage of aluminium is that it is recyclable and compatible with sustainable development policies. Considering these benefits, it is a wise decision to choose aluminium caps for your packaging. They are recyclable and look good in a wide variety of products. So, you don't have to choose between colour and design, because they are both equally functional.

If you're storing sensitive products in a refrigerator, a 70mm screw cap can provide an airtight seal. The built-in Rieke Flexspout provides a smooth pour. In addition to the advantages of screw caps, they are also easy to use. They're also cheaper than glass or metal. They're ideal for keeping your products clean and free from contaminants. The best part is, they're available in a variety of colors, so you're sure to find a screw cap to suit your needs.

Plastic Screw Caps are usually made with an injection moulding process. In order to create the screw thread, an inner moulding needs to be unscrewed. After the moulding is complete, the two moulded parts are then separated. The inner mould part defines the screw thread, while the outer mould part is the outer surface. After cooling, the inner mould part unscrews from the stationary moulding, while the outer mould part defines the external surface of the cap.

The process for making a Plastic Screw Cap starts by creating the mould tool. A mould tool is made of a composite material that defines a mould cavity. It is typically closed, with the outer mould part 35 withdrawn from the interior mould part 33. Once moulding is complete, the outer mould part lifts off to expose the freshly moulded cap. Afterwards, the tubular mould part rotates relative to the inner mould part and the cap ejects from the inner mould part.

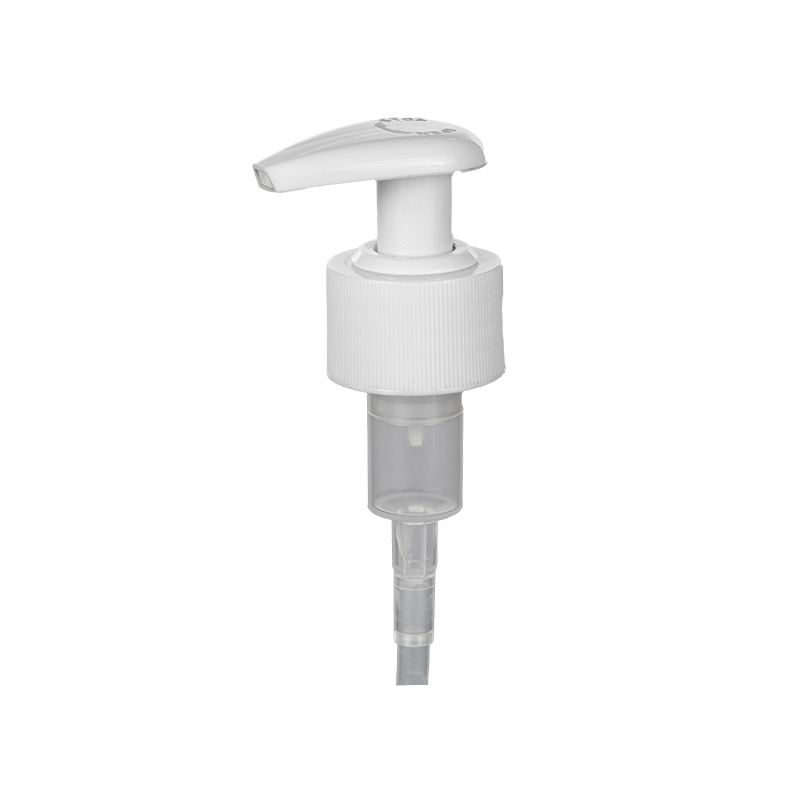

Screw Caps are a common type of closure. They screw onto a container's threaded lip and fit tightly. They are used on a wide variety of products, including water bottles, soda cans, and many more. They are also used in sports bottles, as the central blue piece allows water to pass through. In addition to the screw caps, there are also many types of jugs that feature an airlock.